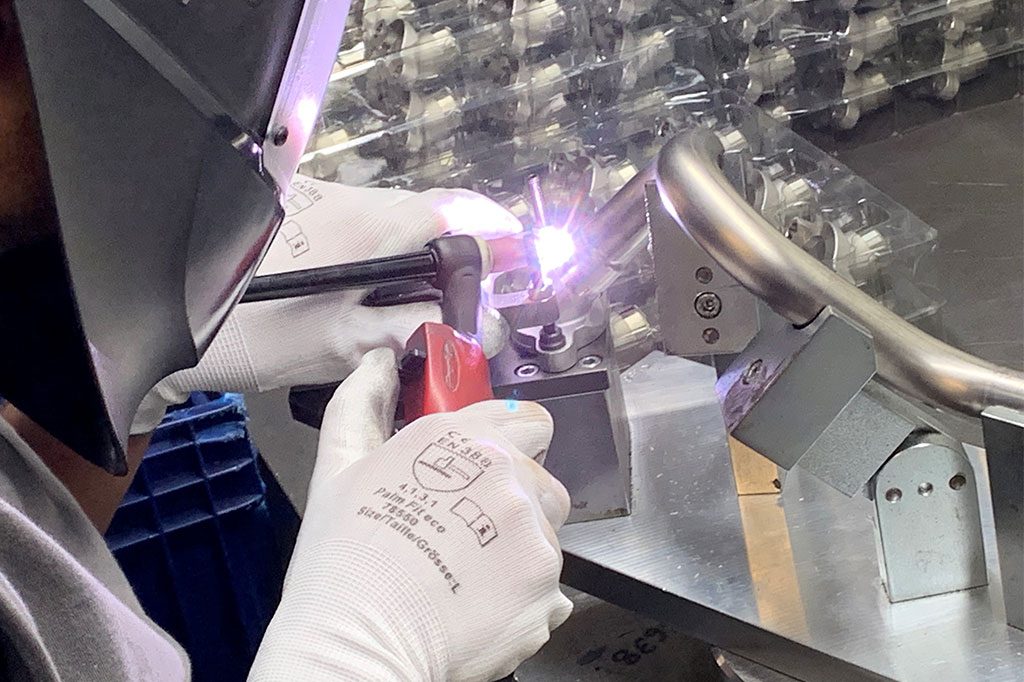

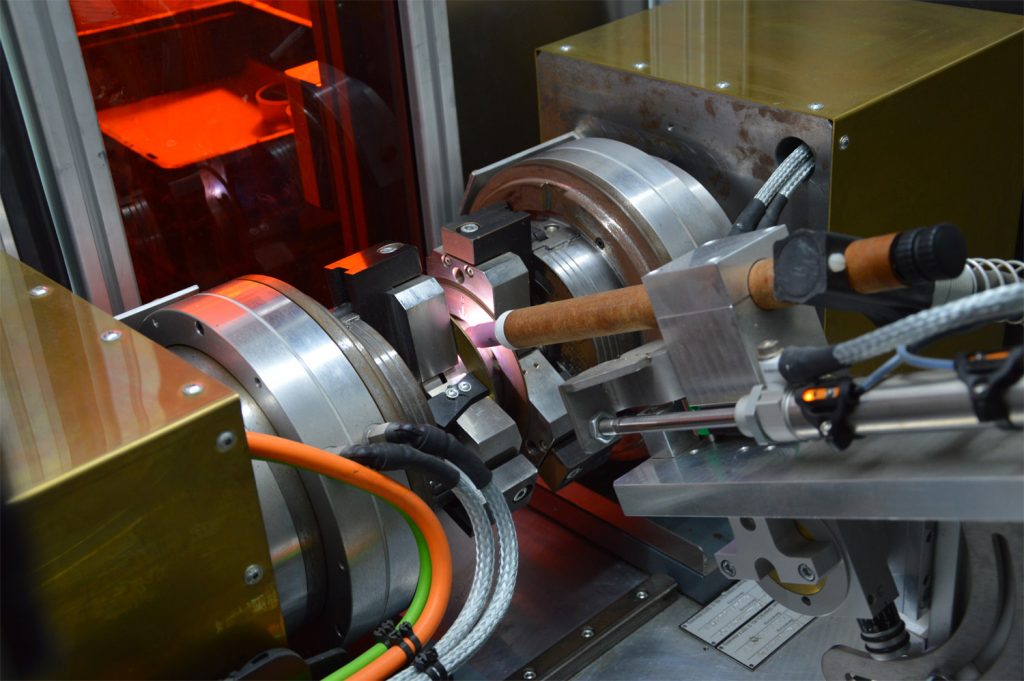

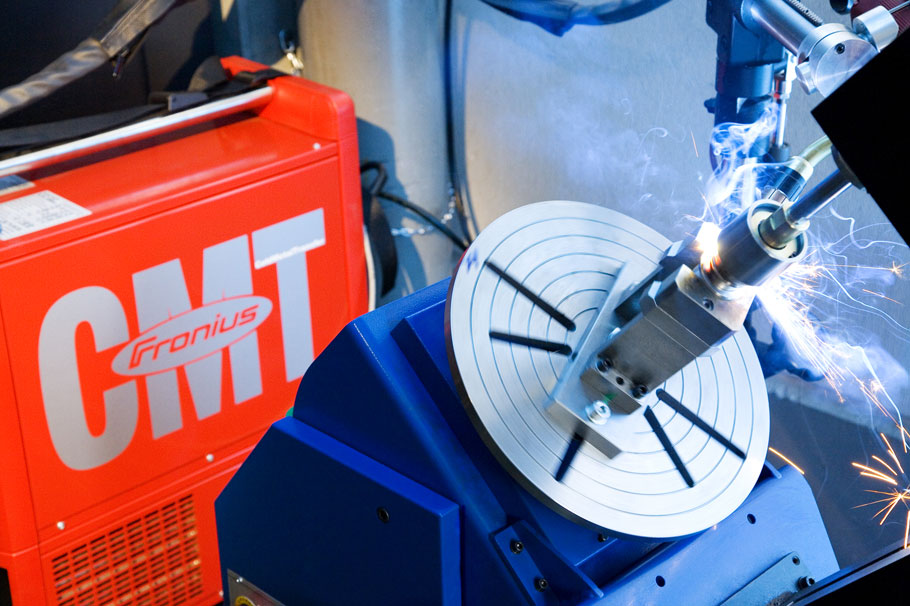

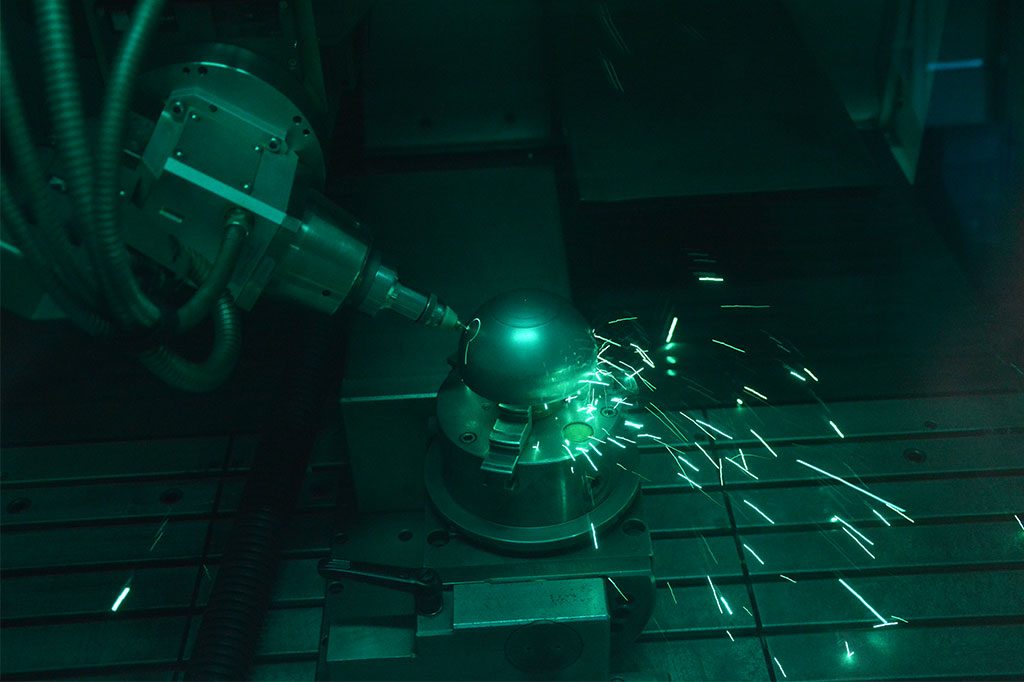

Mit modernsten Fertigungstechnologien fügen wir Halbzeuge zu Serienteilen, manuell – halbautomatisch – vollautomatisch.

Das Ergebnis ist eine Komplettlösung die sich sehen lassen kann, profitieren Sie von unserer Erfahrung in der Schweißtechnik.

Wir bieten hervorragende Lösungen im Bereich der Schweißtechnik

Im Jahr 2008 wurde die Schweißtechnik Burkhard GmbH gegründet und ergänzt seitdem die Burkhard Group als eigenständiges Unternehmen. In dieser Konstellation bieten wir unseren Kunden als Lohndienstleister die komplette Wertschöpfungskette der Fügetechnik und Wärmebehandlung von Metallen.

Qualifizierte Mitarbeiter und ein moderner Maschinenpark ermöglichen es uns, sowohl Einzelteile wie auch Serienbauteile zu bearbeiten, die Wertschöpfungstiefe bestimmt allein der Kunde.

Kurze Reaktionszeiten, flexible Produktionsplanungen und ein Backup für unsere wichtigsten Maschinen geben unseren Kunden die Sicherheit, mit uns den richtigen Partner zu haben.

Ihre Ansprechpartner

Schweißtechnik Burkhard GmbH

Julius-Probst-Straße 7

D-87600 Kaufbeuren

Unsere Kompetenz – Schweißverbindungen mit höchster Festigkeit

Profitieren Sie von unserer jahrelangen Erfahrung in der Schweißtechnik, Sie definieren das Ziel, wir setzen es um und das seit über 10 Jahren. Bei uns finden Sie alle gängigen Fertigungsverfahren, für jeden Anwendungsfall haben wir die passende Lösung.

Unsere Leistungen

Anwendungsbeispiele

Eine gute Vorbereitung ist die beste Basis

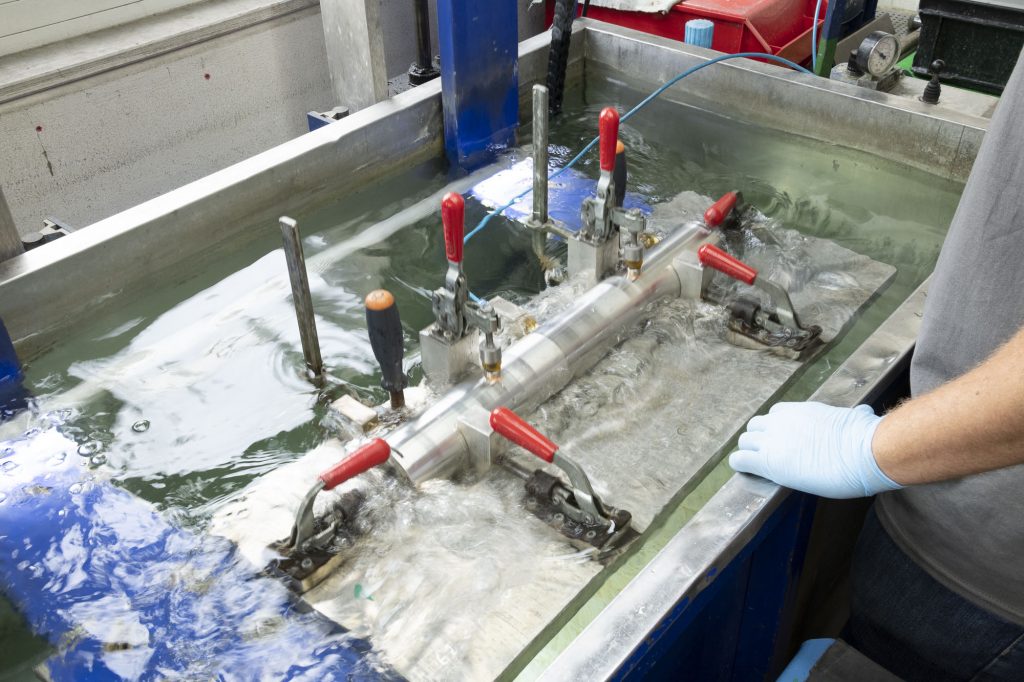

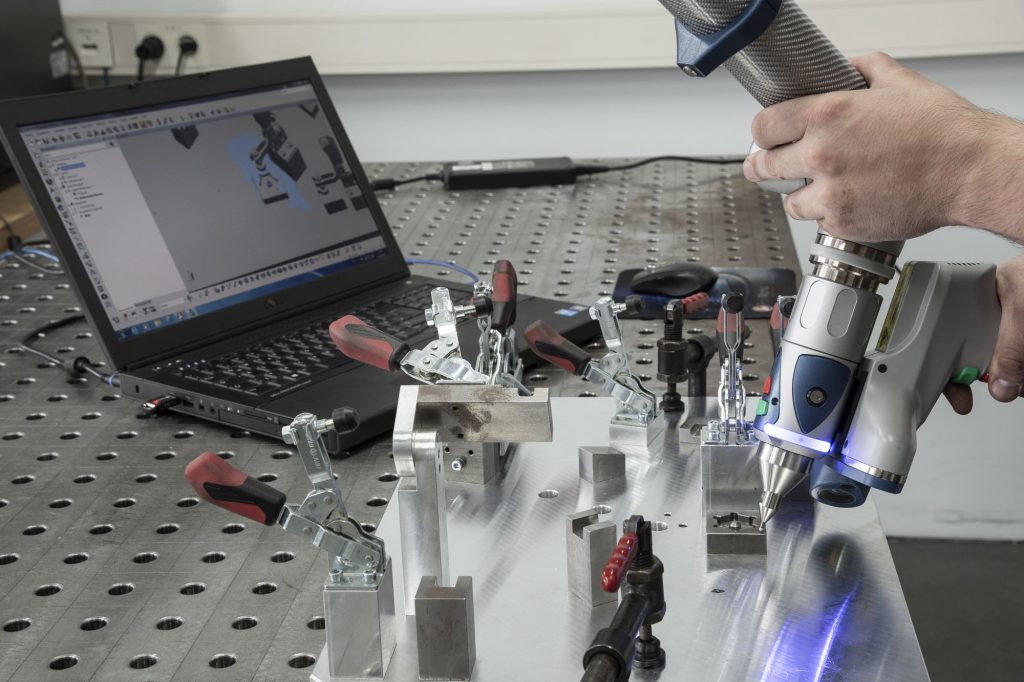

Die Bauteilvorbereitung und Bauteilmontage ist die Basis für alle nachfolgenden Prozesse.

Je besser die Basis, desto besser das Endergebnis. Wir planen mit Ihnen die komplette Prozesskette, damit sind Sie auf der sicheren Seite.

Unsere Leistungen

Anwendungsbeispiele

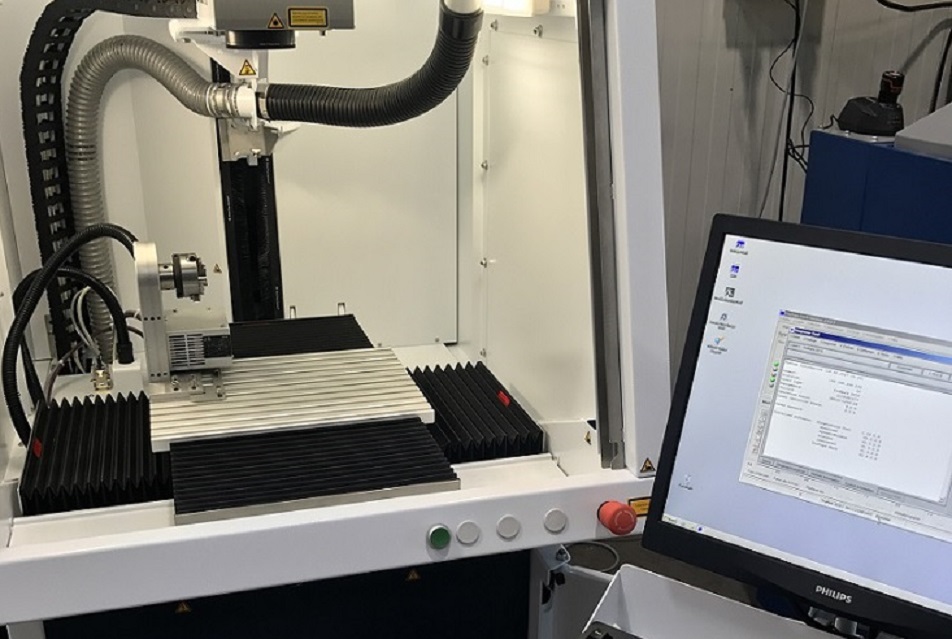

Unser Ziel: besser als bestellt

Qualität kennt keine Kompromisse. Jedes Bauteil wird mit gleichbleibender Qualität bearbeitet – egal wie komplex – egal wie oft.

Wir kontrollieren sowohl fertigungsbegleitend, wie auch final am Ende des Produktionsprozesses und bieten viele Leistungen auch als Dienstleistung an.

Unsere Leistungen

Anwendungsbeispiele

- Schweißen

-

Unsere Kompetenz – Schweißverbindungen mit höchster Festigkeit

Profitieren Sie von unserer jahrelangen Erfahrung in der Schweißtechnik, Sie definieren das Ziel, wir setzen es um und das seit über 10 Jahren. Bei uns finden Sie alle gängigen Fertigungsverfahren, für jeden Anwendungsfall haben wir die passende Lösung.

Unsere Leistungen

Anwendungsbeispiele

- Bauteilmontage, -vorbereitung

-

Eine gute Vorbereitung ist die beste Basis

Die Bauteilvorbereitung und Bauteilmontage ist die Basis für alle nachfolgenden Prozesse.

Je besser die Basis, desto besser das Endergebnis. Wir planen mit Ihnen die komplette Prozesskette, damit sind Sie auf der sicheren Seite.

Unsere Leistungen

Anwendungsbeispiele

- Endprüfung, -bearbeitung

- QS / Labor

-

Unser Ziel: besser als bestellt

Qualität kennt keine Kompromisse. Jedes Bauteil wird mit gleichbleibender Qualität bearbeitet – egal wie komplex – egal wie oft.

Wir kontrollieren sowohl fertigungsbegleitend, wie auch final am Ende des Produktionsprozesses und bieten viele Leistungen auch als Dienstleistung an.

Unsere Leistungen

Anwendungsbeispiele

Übersicht

Die Leistungen der Schweißtechnik Burkhard auf einen Blick

Schweißen

Bauteilmontage, -vorbereitung

Endprüfung, -bearbeitung

QS / Labor

Ihre Vorteile…

Qualität – Made in Bavaria

Bereits 1998 erhielten wir unsere erste Zertifizierung. Doch unser Ziel ist es nicht, der ISO-Norm zu genügen, sondern unsere eigenen, deutlich höheren Qualitätsstandards zu erfüllen.

Vor diesem Hintergrund erfolgt auch die kontinuierliche innerbetriebliche Weiterbildung, um unsere Teams fachlich und qualitativ immer auf dem neuesten Stand zu halten.

Starten Sie mit uns ein Projekt

Sie liefern uns Ihre Anforderung – wir liefern Ihnen eine Lösung! Hinterlassen Sie uns einfach über nebenstehendes Formular Ihre Idee zu Ihrem geschweißten Wunschprodukt.

Mit unserer langjährigen Erfahrung erarbeiten wir gemeinsam mit Ihnen die beste Herangehensweise und eine passende Lösung.

Unser Team und unser leistungsfähiger Maschinenpark sind jeglicher Herausforderung gewachsen. Wir bieten Ihnen ein Ergebnis, das weit über den herkömmlichen Standards liegt.

Schreiben Sie uns jetzt an. Sie erhalten umgehend eine fachspezifische Beratung aus unserem Hause.